Introduction

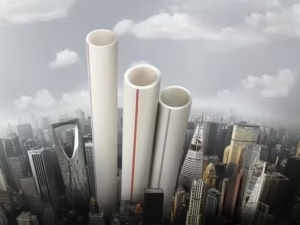

Are you looking for sustainable and efficient infrastructure solutions for your projects that lead to success and sustainability? The solution in choosing the right plastic pipe fittings.

The choice of plastic pipe fittings is one of the reasons for the success of the largest construction projects in Saudi Arabia

In today’s construction world, the importance of high-quality plastic pipes, whether it’s a residential, commercial or industrial project, cannot be ignored.

Many contractors, engineers and investors face significant challenges such as searching for certified products, meeting standard specifications, and ensuring continuity of supply.

Here comes the role of the Fabco Plastic Factory, the leader in the plastic pipe industry in Saudi Arabia since 1975.

The plant offers integrated solutions that meet local and international standards, to be the optimal choice for water, electricity, communications and sanitation projects.

Today in this article we review some common questions:

- What are plastic pipe fittings?

- Types of plastic water pipes and their various applications?

- What type of installation is used in PVC tubes?

- Modern technologies in welding and installation of plastic pipes?

- Innovative solutions to market challenges from Fabco Factory?

Follow us to learn more, ….

What are plastic pipe fittings ?

Plastic pipe fittings are all parts and accessories that are used to connect pipes, divert them, or control the flow of water and fluids.

These facilities include elbows, connectors, sockets, flexible connections and sockets, and are the basis for ensuring the efficient and safe functioning of the distribution network.

Why are plastic pipes the best choice in our time?

With the continuous development of the building and infrastructure construction sector, the plastic pipe industry has witnessed a remarkable development making it the first choice for engineers and contractors.

Investing in high-quality equipment such as the Fabco Plastic Factory Plant contributes to:

- High resistance to corrosion and rust, ensuring longer life for the entire system.

- Easy installation and maintenance, which reduces the overall costs of the project.

- Its light weight facilitates transportation and installation without the need for heavy equipment.

- Reduce leaks and repetitive maintenance work.

- Ensure compliance with Saudi legislation regulations (SASO) and special requirements such as Aramco.

- Improving the efficiency of water, sanitation and irrigation systems.

- Extend the life of the project and reduce operational costs in the long run.

Plastic water pipes also play a pivotal role in building maintenance, providing long-term solutions that reduce the need for continuous maintenance.

Types of plastic pipe fittings

There are many types of plastic pipes in the Fabco Plastic Factory:

1. PVC pipe fittings

- The most common in sewage systems and pipes and water conduction.

- It is lightweight, rust-resistant, and easy to install using a plastic pipe welding machine or special adhesives.

- PVC pipes are available in multiple sizes, such as Table 40 for pipes, to suit domestic and industrial uses.

2. Equipment for CPVC pipes

- Designed to withstand high temperatures, it is ideal for hot water uses.

- It is compatible with many international standards such as ASTM.

3. PPR pipe fittings

- Most commonly used in water pipe networks PPRs within modern buildings.

- It has high strength, corrosion resistance and easy installation via thermal welding.

4. HDPE pipe fittings

- Ideal for major projects.

- It is widely used in plastic irrigation pipes and agricultural projects.

- High flexibility and resistance to breakage and pressure, making it suitable for large water networks.

- Resistance to harsh environmental conditions.

Modern technologies in welding and installation of plastic pipes

The Fabco Plastic Factory is keen to use the latest plastic pipe welding machine technology, to achieve strong and tight connections that ensure no leaks.

These modern technologies also help reduce installation time and ensure higher quality of connections.

What are the three common types of tubes?

- Fusion Welding: Most commonly used with PPR and HDPE pipes.

- Solvent Cement Jointing: Commonly used with PVC pipes.

- Compression fittings (most often used in some irrigation systems and simple extensions).

Fabco Plastic Factory innovative solutions to meet market challenges

Meet the challenges of quality and reliability

In an environment that demands the highest quality standards, FAPCO offers certified and tested products that meet the most difficult technical requirements.

This helps contractors and engineers avoid quality problems that may lead to project delays.

Supply chain and delivery

Through a strong distribution network and professional supply chain management, the factory ensures the timely availability of products.

This helps to avoid project delays and additional costs.

Factors influencing prices of PVC and economic standards

Water pipe prices are affected by several factors, including the quality of raw materials, international standards applied, volume of production, and fluctuations in the global market.

But it is important to understand that investing in high-quality pipes saves long-term maintenance costs. Here comes the role of choosing a reliable plastic pipe manufacturer such as the Fabco Plastic Factory.

The importance of choosing reliable plastic manufacturers

When searching for plastic pipe factories in Saudi Arabia, the Fabco Plastic Factory is one of them and has been a pioneer in this field since its inception in 1975.

The factory is characterized by adherence to the highest international quality standards such as ASTM, DINO, BSO and SASO, ensuring products that meet the needs of the local and global market.

Features of dealing with Fabco Plastic Factory

Experience and specialization

With more than 45 years of experience, FAPCO offers integrated solutions that meet the needs of various sectors from residential to industrial.

This long experience translates into a deep understanding of the needs of the Saudi market and the region.

Quality and international standards

The factory is committed to applying the highest international quality standards, ensuring products that excel in performance and reliability.

This commitment to quality makes FAPCO products a reliable choice for sensitive and important projects.

Diversity of products

With a catalog of more than 124 products, Fabco Factory provides comprehensive solutions for all the needs of plastic pipe and plastic pipe fittings.

This saves customers the trouble of dealing with multiple suppliers.

Integrated solutions for different sectors

- Contractors and building construction projects receive high-quality water pipes that reduce the costs of building maintenance work.

- Consultants can rely on a broad product catalog of over 124 products to meet their technical needs.

- Suppliers and traders benefit from continuous and reliable supply, with competitive prices in the prices of PVC pipes and water pipes.

- Government agencies ensure compliance with the official standards required for the national infrastructure.

Answer the most common questions

What is Pipe Installation and its importance?

The installation of plastic water pipes is a technical process that requires experience and high accuracy.

Installation includes several stages from design and planning, through actual installation, to testing and commissioning.

The goal of proper installation is to ensure that water flows efficiently without leaks or technical problems.

What type of installation is used in PVC tubes?

PVCs use a variety of installation methods including heat welding, mechanical connections, and screw installations.

Choosing the right method depends on the type of application and the pressure to be endured.

What does PVC mean?

It is short for “polyvinyl chloride”, i.e. polyvinyl chloride.

What is Table 40 for Pipes?

It is a classification that determines the wall thickness of PVC pipes and is suitable for many domestic and industrial applications.

What is the proper size of the tubes?

It depends on the nature of the project, the amount of flow required, and the target operational pressure.

Conclusion

Choosing the right plastic pipe fittings is not just a technical decision, but a strategic investment in the long-term success of your project.

With its experience since 1975 and its commitment to the highest international quality standards.

Fabco Plastic Factory offers you integrated solutions that ensure the success of your project and save you future costs.

Whether you are a contractor looking for high-quality water pipes, an engineer who needs cutting-edge technology solutions, or an investor seeking to ensure the sustainability of his project, Fabco is your trusted partner on the journey of success.

Continue with us now:

Address: P.O. Box 150, Second Industrial City, Dammam 31411

Phone: +966 66 200 9200

E-mail: info@fabcoplastic.com

Location: fabcoplastic.com

Fabco Plastic Factory – committed to quality